Abro Balancing Machine Services in Malaysia

TECHNICAL OFFER FOR ‘ABRO’ ARH SERIES MACHINES

(1) APPLICATION

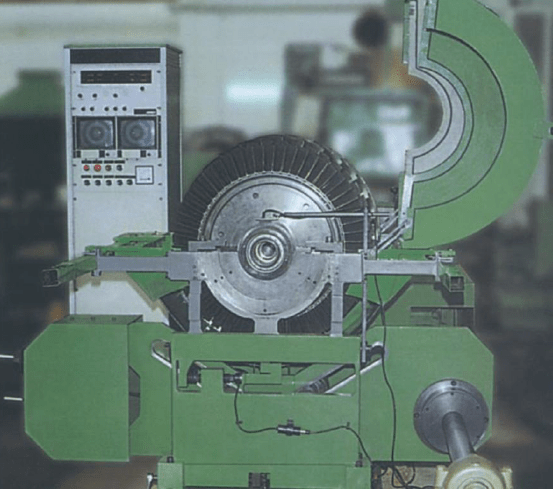

The ARH series machines are used primarily for high accuracy balancing of aircraft and marine turbines, compressors and parts. These are assembly balancing machines which can support complete craddles supported on the two pedestals. This enables complete assemblies, including bearing housings to be supported and balanced on the machine.

The machine pedestals have standard ARP type supports which can directly support individual bearings. Roller supports is another system available for directly supporting shafts/journals. A tiebar arrangement is offered for connecting LHS and RHS pedestals for convenience and additional rigidity.

The versatile ARH series machines are also being used by the Aerospace Industry, the Textile Industry and other industry for balancing turbines, bobbins chucks, armatures etc.

(2) EXPORT OF ABRO TECHNOLOGY TO U.K, ITALY AND USA

Following reputed balancing machine manufacturers have been making balancing machines since early 1920’s.

- ELETTRORAVA SpA (ITALY)

- GIESLER LTD (U.K)

- PRO-BAL (Formerly Stewart Warner Inc.) (USA)

The above manufacturers have purchased ABRO designs and have shifted to ABRO

designs for the machines they make in their plants in London, Rochester, Torino,

Barcelona & South Carolina.

(3) HARD BEARING DESIGN

The offered machines are of HARD BEARING design which permits changing jobs without any calibration or trial runs by simply dialing 5 job dimensions as shown on page 4 of our catalogue. After which the very first run gives you the correction values in grams.

(4) SYNCHRONOUS FILTERS

All modern balancing machines have filters to cut out spurious vibrations (noise) while measuring unbalance. ABRO use synchronous filters (Automatic Speed Tracking filters) which eliminate the need for manual tuning or adjustments.

(5) ARH REFERENCES:

The ARH series machines are proven machines with high accuracy and unmatched technical features. Given below is a part list of the users of ARH series machines for precision highspeed or lowspeed balancing.

(i) HAL-Koraput 7 nos. ARH-3 & ARH-110 machines for the balancing of MIG Supersonic Aircraft Engines.

(ii) HAL-Koraput (Sukhoi Division) 3 nos. ARH-12 & ARH-60 machines for Sukoi Supersonic Aircraft engines.

(iii) AIR FORCE

Chandigarh. For MI-8 Helicopters (TV-2 and TV-3) Engines).

For AN-32 aircraft (AI-20 engines). 2 nos. ARH-60.

Also updated smaller machines of size ARH-12.

(iv) AIR FORCE, Kanpur 1 No. ARH-110 machine and 3 Nos. Upgradation for MIG Supersonic Aircraft Engines. 1 No. ARH-3

for highspeed Aircraft parts.

(v) AIR FORCE, Nasik 1 No. ARH-3 for high speed parts of MIG Aircraft.

(vi) NAVY 3 nos. ARH-110 and ARH-200 are working with Marine Gas Turbine Overhaul Centre, Visakhapatnam. (INS-EKSILA)

Annexure-0112/ARH/ Page 3 of 4 VA

(vii) PEEMAC, Bangalore ARH-110 for balancing Turbines.

(viii) AIR LANKA ARH-3 machine for aircraft rotors.

(ix) HAL-Kanpur ARH-12 machine for aircraft rotors.

(x) HAL-Lucknow ARH-3 machine for aircraft rotors.

(xi) Ingersol Rand (I) Ltd ARH-3 for turbocharger and compressors

(xii) Army Base Workshop, Meerut ARH-30 for engines.

(xiii) LMW, Coimbatore ARH-3 for textile spindles.

(xiv) Lakshmi Synthetics Ltd ARH-12 for bobbin chucks, spindles etc.

(xv) Spinfab Machinery (India)Pvt.Ltd, Faridabad. ARH-3 for textile parts.

(xvi) LMW, Coimbatore ARH-3 for Textile spindles

(xvii) ATE, Ahmedabad ARH-3 for textile flyers.

(xviii) IOCL, Chennai ARH-12 for bobbin chucks & spindles.

Tooling have been supplied by us for the balancing of following:

- MIG-21 and MIG-29 Fighter Aircraft.

- 53 engine of MIRAG Fighter Aircraft.

- MI-8 Helicopters.

- AN-32 Transport Aircraft

- MGTOC, Visakhapatnam (INS-EKSILA)

- Operating speed balancing of bobbin chucks.

- Operating speed balancing of textile spindles

(6) STANDARD EQUIPMENT

- (a) One test rotor of our own design with removable calibrated unbalance weights

- to facilitate checking the machine’s accuracy at any time.

- (b) Various tools for the operation of the machine.

- (c) Surface belt drive

- (d) 2 nos. safety hold-downs.

- (e) 12 nos. fuses

- (f) 6 nos. bulbs

- (g) 2 sets of operating instruction manuals.(Additional set @ Rs.450/- per set)

(7) PRICES

As per covering letter.

(8) TERMS & CONDITIONS

As per enclosed Terms & conditions. Annexure-0112/ARH/ Page 4 of 4 VA

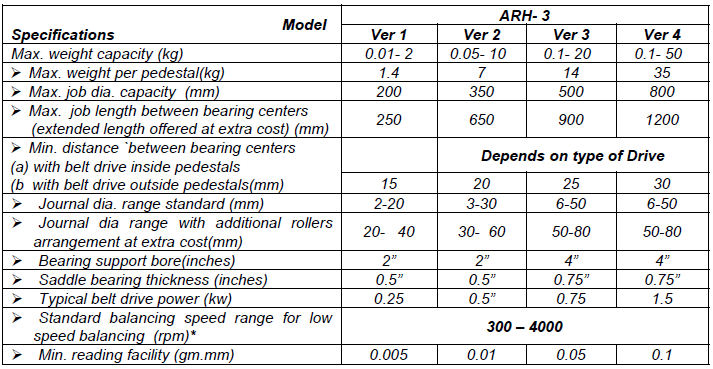

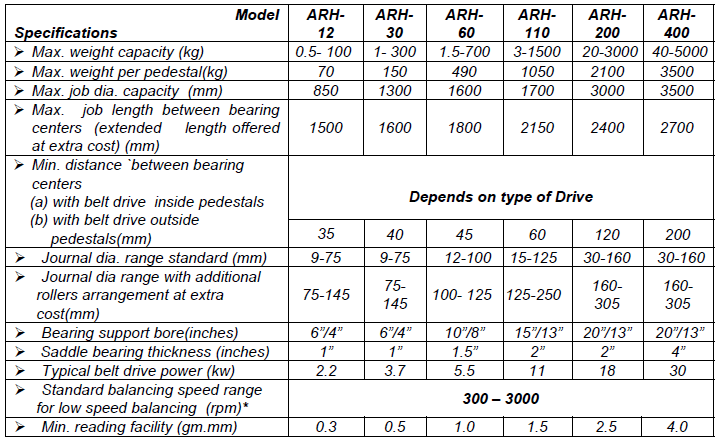

(9) TECHNICAL SPECIFICATIONS:

ARH SERIES MACHINE – SMALL

ARH SERIES MACHINE – LARGE

* For high speed balancing, suitable drive has to be provided.