Conditioning Monitoring of Rotating Equipment

Program Goals

Elimination of machine breakdowns.

Able to anticipate and accurately plan for maintenance needs.

To increase plant production readiness by significantly reducing the chance of a breakdown during operations

Reduced expenditures for spare parts and labor. Machines that fail while in service often cost ten times as much to repair than if the repair were anticipated and scheduled.

Predictive maintenance.

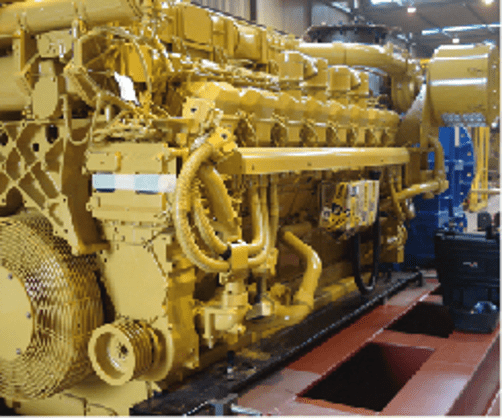

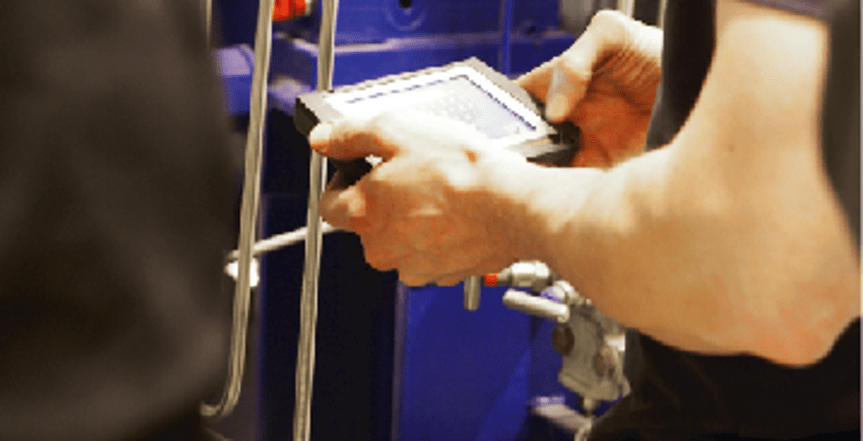

Vibration Measurement

Vibration can be considered to be the oscillation or repetitive motion of an object around an equilibrium position.

Vibration of an object is always caused by an excitation force. This force may be externally applied to the object, or it may originate inside the object.

Rate (frequency) and magnitude of the vibration of a given object is completely determined by the excitation force, direction, and frequency

Forces are dependent upon the machine condition, and knowledge of their characteristics and interactions allows one to diagnose a machine problem.

Some Common Machine Problems That Generate Mechanical Vibration Misalignment Unbalance

Worn belts & pulleys Bearing Defects

Hydraulic Forces Aerodynamic Forces

Reaction Forces Reciprocating Forces

Bent Shafts Rubbing

Gear Problems Housing Distortion

Certain Electrical Problems Frictional Forces